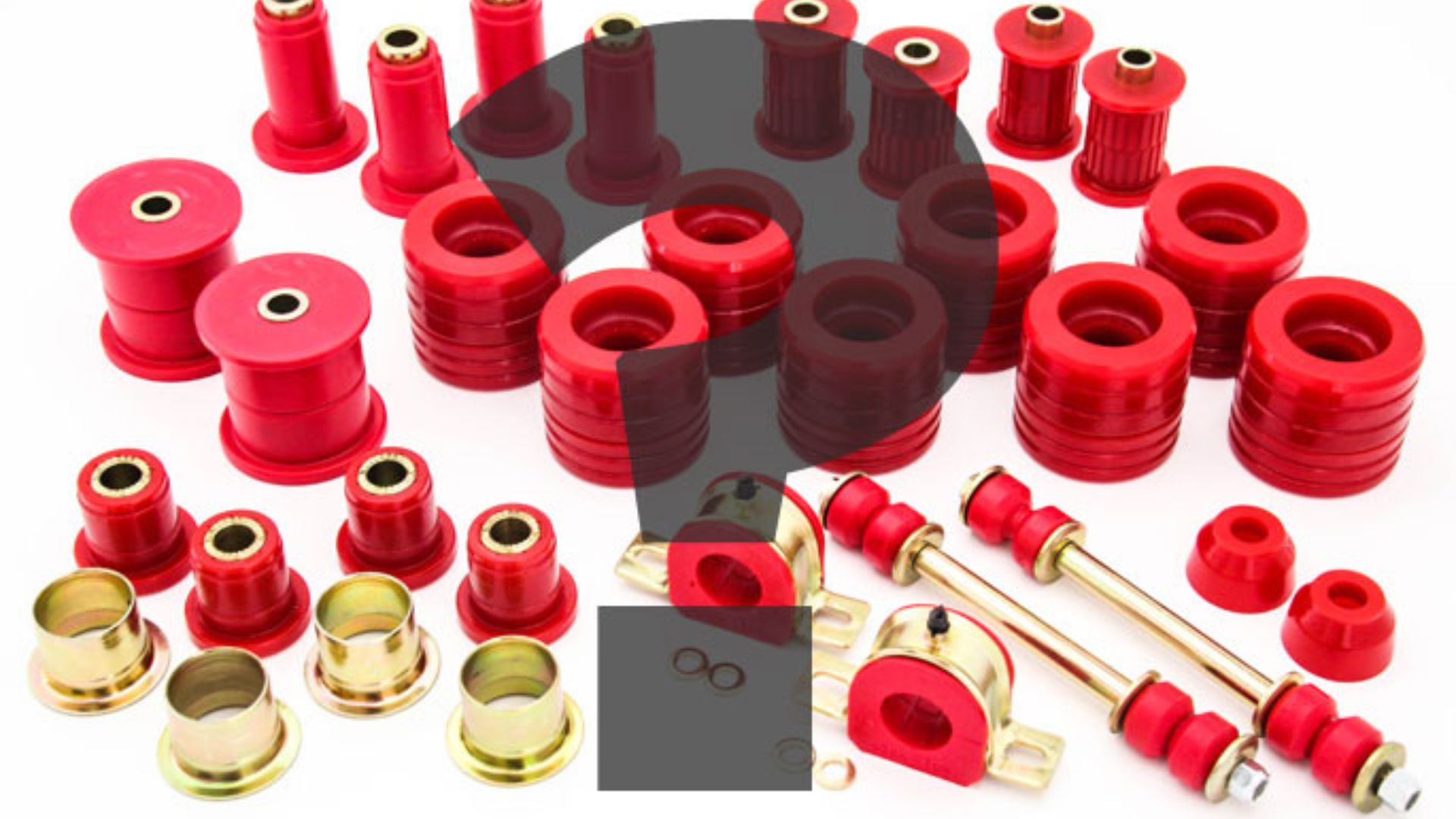

Polyurethane bushings, often referred to as poly bushings, are commonly used in suspension systems due to their durability and performance benefits. They provide a firmer ride than rubber bushings, enhancing vehicle handling. However, a key consideration for many vehicle owners and enthusiasts is the break-in period for poly bushings. In this article, we will explore the break-in process for poly bushings, how long it takes, factors that influence this period, and tips for ensuring your bushings perform optimally.

What Are Poly Bushings?

Polyurethane bushings are synthetic elastomer bushings that are stiffer than traditional rubber bushings. These bushings are used to support and cushion parts of the vehicle’s suspension system, offering improved handling and control, especially under load and in high-performance applications.

Advantages of Poly Bushings:

Durability: Polyurethane is highly resistant to wear, aging, and the elements. Poly bushings last longer than rubber ones.

Performance: They reduce body roll, allowing for more precise handling in performance driving.

Customizability: Available in various hardness levels, poly bushings can be tailored to specific vehicle setups.

Downsides of Poly Bushings:

Noise: They tend to squeak if not lubricated properly.

Firmness: The stiffer nature can result in a rougher ride compared to rubber bushings.

What Is the Break-In Period for Poly Bushings?

The break-in period for poly bushings refers to the time it takes for the bushings to settle into their new role after installation. During this period, the bushings conform to the specific movements and loads of the vehicle’s suspension system. Although polyurethane is a relatively stiff material, it still requires time to adjust to the unique forces exerted during regular driving.

How Long Does It Take for Poly Bushings to Break In?

Generally, poly bushings take around 500 to 1,000 miles to fully break in. However, the break-in period can vary depending on factors such as driving conditions, vehicle type, and installation accuracy.

Normal Driving Conditions: Under typical driving conditions, such as city or highway driving, the break-in period is usually about 500 miles.

Performance Driving: For vehicles that are driven aggressively, such as on a race track, the break-in period may be shorter due to the higher forces exerted on the bushings.

Off-Road Conditions: Off-road vehicles may experience a longer break-in period, as the irregular terrain can cause the bushings to settle more slowly.

Signs That Poly Bushings Are Broken In:

Smoother Ride: After break-in, the stiffness you feel during the initial drive will soften slightly, providing a smoother and more controlled ride.

Reduced Noise: Poly bushings can make noise when new, especially if not lubricated properly. After breaking in, this noise typically decreases or stops.

Improved Handling: As the bushings conform to the suspension components, you’ll notice better handling and more predictable vehicle responses.

Factors That Influence the Break-In Period

Several factors affect how long it takes for poly bushings to break in. Understanding these factors can help you get the best performance from your new bushings.

Driving Style

Aggressive Driving: If you frequently drive on winding roads or participate in motorsports, your bushings will break in faster due to the higher loads placed on the suspension.

Normal Driving: For regular commuting or highway driving, the break-in period will be more gradual.

Vehicle Type

Heavy Vehicles: Larger, heavier vehicles, like trucks and SUVs, place more strain on the bushings, potentially leading to a quicker break-in period.

Light Vehicles: Smaller vehicles, like sedans or coupes, may require more time for the bushings to settle.

Suspension Setup

Custom Suspension: Vehicles with modified or aftermarket suspension systems may exert more stress on the bushings, leading to faster break-in.

Stock Suspension: A stock suspension setup may result in a more gradual break-in period due to lower forces applied to the bushings.

Environmental Conditions

Temperature: In colder climates, the polyurethane material becomes more rigid, extending the break-in period. Conversely, warm temperatures soften the material, speeding up the process.

Terrain: Off-road driving or driving on rough, uneven surfaces can prolong the break-in period as the bushings endure more varied movements.

Tips for Breaking in Poly Bushings

To ensure your poly bushings perform optimally and break in properly, here are some tips:

Proper Lubrication

Poly bushings require special lubricant to minimize friction and noise. Most manufacturers include this lubricant with the bushings. Applying the lubricant during installation can prevent annoying squeaks and prolong the life of the bushings.

Regular Inspection

After installation, check the bushings periodically for wear, noise, or improper alignment. Look for signs of degradation such as cracking or excessive movement.

Drive Consistently

Consistent driving during the first 500 miles helps the bushings conform to the suspension. Try to avoid abrupt or extreme driving during this period, especially if you’re aiming for a longer bushing lifespan.

Re-Tighten Bolts

Poly bushings may settle slightly after the break-in period, causing bolts to loosen. After driving for a few hundred miles, recheck all bolts and tighten them to the manufacturer’s recommended torque settings.

Common Issues During the Break-In Period

While poly bushings offer excellent performance, certain issues may arise during the break-in period. Here’s what to look out for:

Noise

One of the most common complaints during the break-in phase is noise. Squeaking or creaking sounds can occur due to insufficient lubrication or improper installation. Applying a high-quality grease designed for polyurethane bushings can help eliminate this issue.

Stiff Ride

A firmer ride is to be expected with poly bushings, especially compared to rubber bushings. However, if the ride feels excessively harsh or uncomfortable, it could be due to incorrect installation or the use of bushings that are too stiff for your driving style.

Misalignment

If you notice that your vehicle’s handling feels off after installing poly bushings, misalignment could be the cause. This can happen if the bushings were not installed correctly or if bolts have loosened during the break-in period. A professional alignment check can resolve this issue.

Conclusion

The break-in period for poly bushings is generally between 500 and 1,000 miles, depending on factors such as driving conditions, vehicle weight, and installation quality. While they offer enhanced durability and performance compared to rubber bushings, poly bushings do require time to settle into place. By ensuring proper lubrication, inspecting for wear, and maintaining consistent driving habits, you can optimize the performance of your polyurethane bushings. After the break-in period, you’ll enjoy improved handling and a more responsive suspension system.

ALSO READ:The Radiance Of 1980s Neon Fashion: A Colorful Era Revisited

FAQs

Do Poly Bushings Require Lubrication?

Yes, poly bushings require lubrication to prevent squeaking and ensure smooth operation. Be sure to use a lubricant specifically designed for polyurethane bushings.

Can Poly Bushings Be Too Stiff?

Yes, poly bushings can be too stiff for some drivers, especially those who prefer a more comfortable, cushioned ride. It’s important to choose the right hardness level based on your vehicle and driving style.

Why Are My Poly Bushings Squeaking?

Poly bushings can squeak if they are not properly lubricated during installation or if the lubricant wears off over time. Applying a high-quality bushing grease can resolve this issue.

How Can I Tell If My Poly Bushings Are Worn Out?

Signs of worn-out poly bushings include excessive noise, increased body roll, and noticeable suspension play. Regular inspection will help you catch these signs early.

Can I Install Poly Bushings Myself?

Yes, you can install poly bushings yourself, but it requires mechanical knowledge and the right tools. If you’re unsure, it’s best to have a professional perform the installation to avoid misalignment or improper torque.